ROBOTIC WELDING APPLICATIONS:

Welding tasks are part of industrial robotics since its beginning several decades ago. In it Robotics we have designed, manufactured and sold robotic welding applications for many years. These applications have covered the most common types of welding, such as MIG, TIG, spot, plasma…, hence we have acquired great experience in this field. From little, compact, efficient and high productive cells up to huge gantry systems of 25 m length, capable of welding extremely large pieces, including advanced laser joint tracking systems. These applications have different peripheral elements, depending on their configuration: turntables and turning machines, tracks for linear movement, gantry systems with inverted robots. All of them are equipped with servo-controlled positioning with precision gearboxes (zero backlash).

SYSTEMS WITH “H TYPE” TURNTABLE

Robotic welding cell with double robot and turntable of 180°. Tools on turning machines servo-controlled.

Robotic welding cell with inverted robot and turntable of 180°. Tools on fixed stations.

SYSTEM WITH VERTICAL ROTATION

Robotic welding cell with triple robot and servo-controlled vertical central turning system. Pneumatic tools on servo-controlled turning machines. It has a robot for automatic loading and unloading of parts.

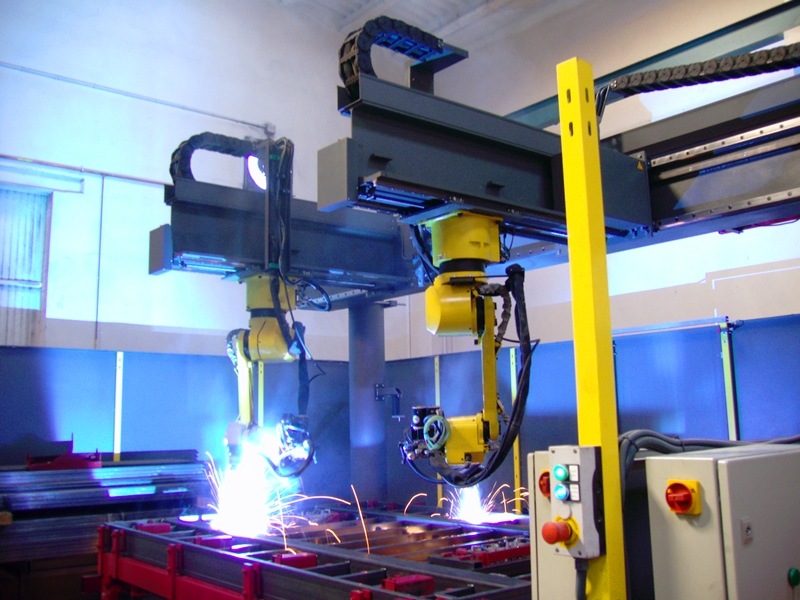

GANTRY SYSTEMS

Robotic welding cells with inverted robot on elevated track. They can have several robots on the same track with servo-controlled movement in X, Y, Z.

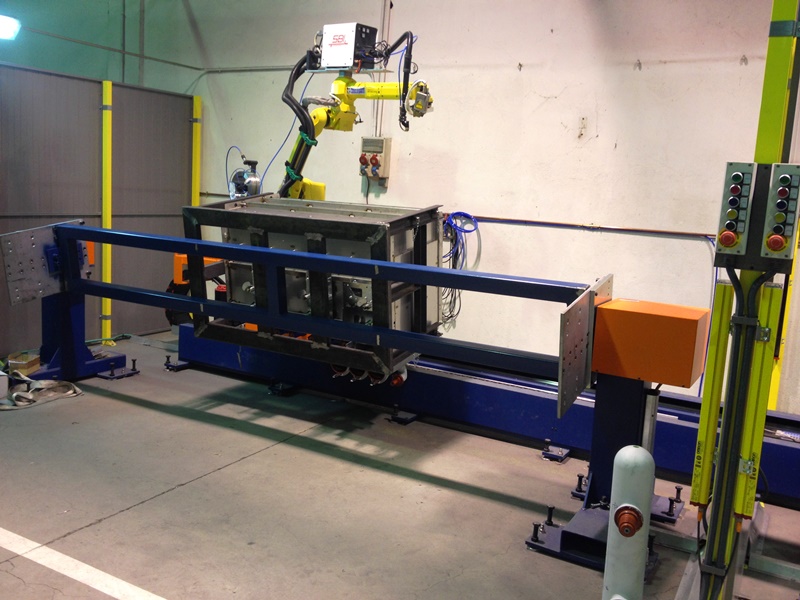

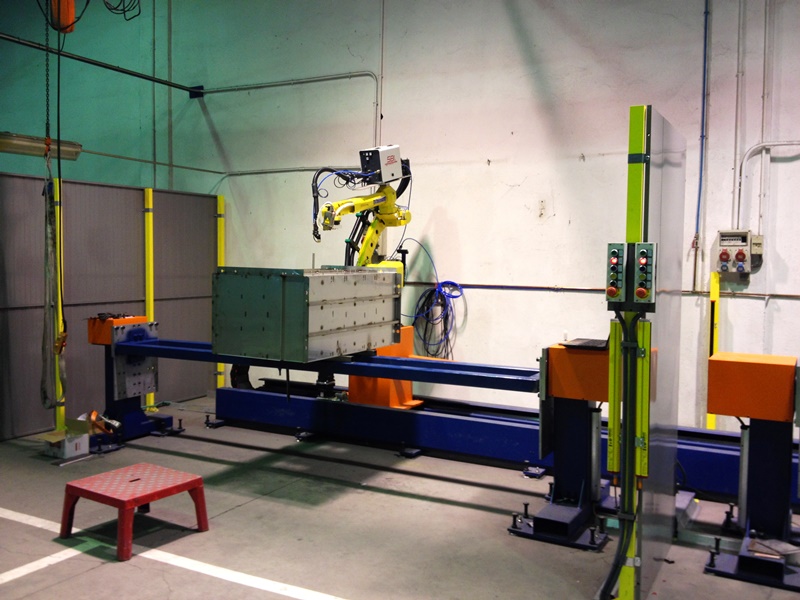

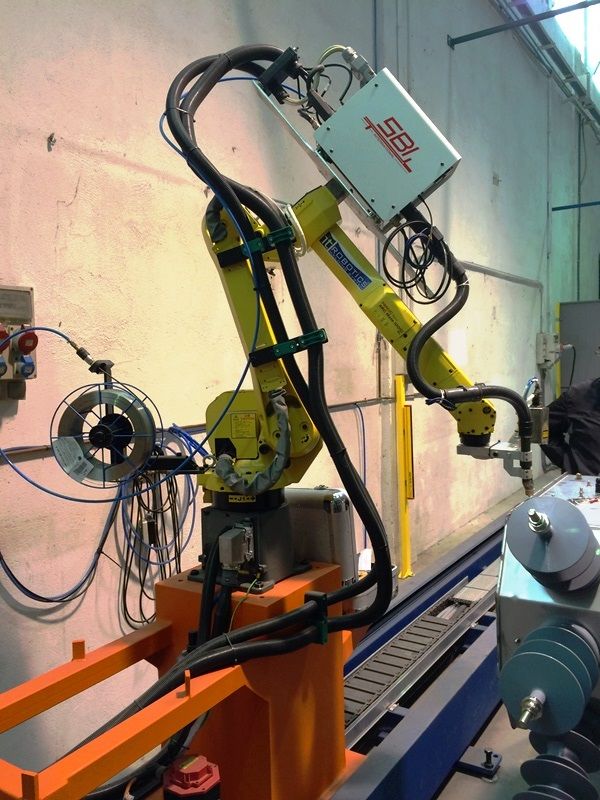

SYSTEMS WITH LINEAR MOVEMENT TRACK

Robotic plasma arc welding system with robot on servo-controlled track for linear movement. Positioning of the part to weld over 2 servo-controlled turning machines in line. It includes laser joint tracking system.

Robotic welding cell with double robot on servo-controlled track and laser joint tracking system.

Other welding applications with robot on servo-controlled track.